Hero Copy

Whether your material handling challenge involves small, simple parts or large complex assemblies we offer the design and fabrication services to create container and racking systems to meet the need. For decades we’ve served up solutions for the aerospace, automotive, plastic, glass, fiberglass, military and SMC industries—from concept to design to prototype to full-service manufacturing.

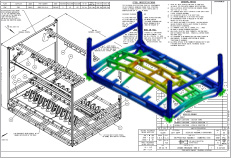

Solutions include packaging trays, bar dunnage, flipper dunnage, shipping trays, specialty pallets, dunnage trays and extend to complex steel racks and racking systems for products as diverse as airplane components to automated automotive seat pallet systems.

Solutions now routinely are called upon to integrate precisely with robotic work cells and feed line equipment.

Of special note is the delivery of complete program management services starting with your part CAD data and turn it into a real-world container solution.